Our Expertise

Our state-of-the-art facilities and experienced team enable us to efficiently recover a wide range of precious metals, including:

Platinum

Extracted from spent catalytic converters achieving high recovery and sustainability.

Palladium

Recovered from catalysts and scrap, ensuring purity and advanced usability.

Rhodium

Extracted from scrap and plating solutions, ensuring performance with specialized methods.

Silver

Extracted from catalysts, sludge, and residues from the glass industry with precision for optimal resource utilization.

Iridium

Recovered from spent catalysts and electronic waste using advanced solvent extraction and ion exchange techniques.

Gold

Recovered from jewelry scrap, plating solutions, and sweeping dust to maximize value efficiently.

Precious Metal Recovery and Refining: A Sustainable Approach

Lumicat is a leading provider of advanced precious metal recovery and refining services. We specialize in transforming spent catalysts and other precious metal-bearing materials into valuable resources.

Catalyst Recovery and Recycling

Efficient Recovery

We employ cutting-edge techniques to maximize the recovery of precious metals from spent catalysts.

Sustainable Practices

Our processes are designed to minimize environmental impact and conserve resources.

Customized Solutions

We tailor our services to meet the specific needs of each client.

Precious Metal Refining

High-Purity Metals

Our advanced refining processes deliver high-purity precious metals that meet the strictest industry standards.

Strict Quality Control

We maintain rigorous quality control measures to ensure the consistency and reliability of our products.

Secure and Reliable

We prioritize the security and confidentiality of our clients' materials.

Why Choose Lumicat Chems?

Decades of Experience

Our team has a proven track record in the precious metal recovery and refining industry.

Advanced Technology

We utilize state-of-the-art equipment and techniques to optimize our processes.

Environmental Commitment

We are dedicated to sustainable practices and minimizing our environmental footprint.

Customer Focus

We prioritize customer satisfaction and build long-lasting relationships with our clients.

By partnering with Lumicat, you can maximize the value of your precious metal-bearing materials while contributing to a more sustainable future.

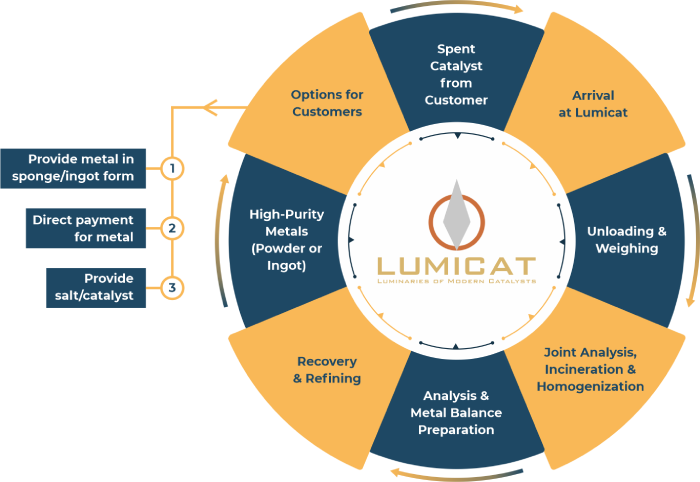

Recovery Cycle Process

At Lumicat, we follow a meticulous recovery cycle to ensure the efficient extraction and refining of valuable metals, delivering precision and sustainability for our clients.

Spent Catalyst from Customer

The process begins when spent catalysts are sourced from customers for recovery and refining.

Arrival at Lumicat

Spent catalysts are delivered to our facility for evaluation and processing.

Unloading & Weighing

The catalysts are unloaded, weighed, and documented to ensure accurate tracking throughout the process.

Joint Incineration, Homogenization and Analysis

The catalysts undergo joint analysis, incineration, and homogenization for optimal metal recovery.

Metal Balance Preparation

Extensive metal balance preparation ensures all materials are accounted for during recovery.

Recovery & Refining

Recovery and refining processes extract and purify precious metals to the required quality.

High-Purity Metals (Powder/Ingot)

Recovered metals are transformed into high-purity forms such as powder or ingot for further use.

Three Options for Customers

1. Receive metal - NABL accredited

2. Receive payment on pre-decided valuation

3. Receive desire salt/catalysts